Powersafe Bi-metal connector are Phase 3 Connections´ solution to connect aluminum cables in high current circuits that incorporate copper cable and busbars. We use Powersafe connectors because they are manufactured with the best raw materials, giving an impeccable friction weld process producing a conductor of high quality. Bi-metallic industrial plugs (which are Powerlock compatible) can be terminated onto flexible aluminum cables so lugs can be replaced with a safer and insulated termination.

Powersafe Bi-Metal Connectors

Powersafe bi-metal connectors for aluminum cables,

safe and powerful power distribution…

Bi-Metal Connectors

Powersafe Bi-Metal connectors are available for inline and panel mount formats in male or female format (source or drain). The electrical connectors are manufactured in colored high-impact thermoplastics, therefore there are several colors available according to line type. The color coding follows electrical industry standards like:

- H308 (EU and UK harmonized)

- Old UK-standard

- AS/NZS 3000:2018 (Australien standard)

- USA

Made in the United Kingdom

Powersafe single pole connectors are 100% manufactured and assembled in the UK by Phase 3 Connectors. The industrial plug´s Powerlock mating system is mechanically keyed and locked, meaning Powersafe cannot be mis-mated or disconnected accidentally under load.

Why use aluminum cable?

Aluminum cables weighs significantly less than copper allowing for cheaper transport costs and easier installations. Aluminum often has 60% cheaper exchange prices.

What raw materials are used?

Phase 3 only use the best metal material in their manufacturing processes: 99,9% pure copper, 99,9 pure aluminum.

How are the metals merged?

Friction welding. A process that generates heat through mechanical friction between metal in relative motion to one another. They test the weld integrity on 1 in 10 welds.

Typical

Application Areas

The dual metal industrial plugs are used as conductors in industries such as:

- Temporary power generation

- Events and stage use

- Renewable energy

- Construction

- Land connection for ships

Standard Powersafe connectors feature copper or copper-based contacts, so they should not be used for direct termination onto aluminum cables as galvanic corrosion may occur. That´s why users of lightweight aluminum cables are using Powersafe bi-metal connectors. They have no problems with overheating during long run times on generators due to innovative engineering solutions to the metal contact band and crimp end (as seen in test reports).

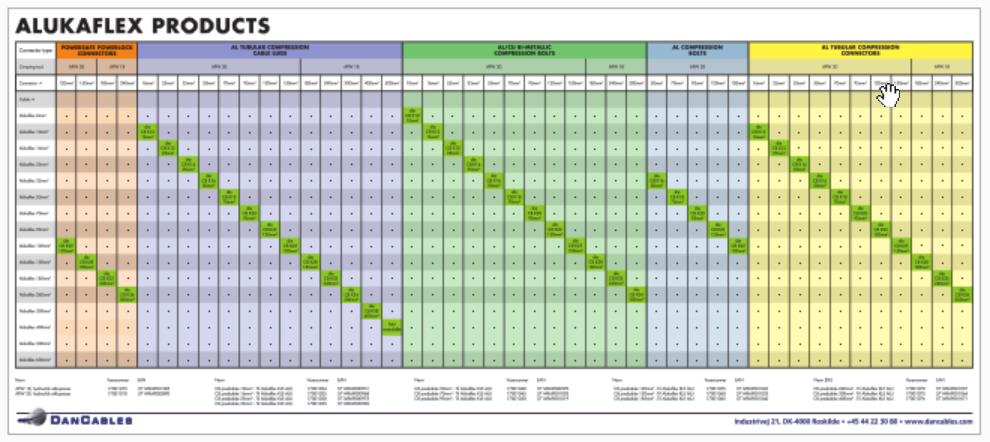

Find the right combination

Cables, connectors, and tools

It is a jungle to figure out which connectorization tool, die, connector or cable lug to use on your cable. A connector allows you to get power from the distribution board and out through the cables. To terminate your connector to your cable you need a tool with the correct die. To help you choose the right combination for your cable dimension we have made a matrix chart where it´s easy to determine which tool, die and connector work together. The Matrix show Alukaflex aluminum cables and HFAL-S and HFAL-M installation cables.